Industrial

Design as an Essential Component for

Assistive Technology Development and Business Success

Daniel Fernando Madrinan-Chiquito

Purdue University

Lafayette, Indiana, United States

dmadrina@purdue.edu

Abstract

New technologies have opened the doors of opportunity to those with disabilities. Exciting new inventions are helping them to live with greater health, productivity, and independence. Moreover, in this new world Industrial Design is finally getting a face with big contributions in the entire product development. These assistive devices are finally drawing the attention to Industrial Design that it deserves from manufacturers who have a financial interest in staying competitive in this lucrative industry. This paper details the benefits of Industrial Design as it is used in the assistive-device industry, as part of a multi-disciplinary process, to create successful and affordable assistive technology products while maintaining consideration of Aesthetics, ergonomics, usefulness, adaptability and production methods.

Keywords-Product Design, Assistive Technology, Industry, Design Thinking

1. Introduction

More than a billion people in the world today experience disability. These people generally have poorer health, lower educational achievements, fewer economic opportunities, and higher rates of poverty (World Health Organization, 2018). Assistive Technology (AT) is a tool to help people with disabilities adapt to different environments allowing them to accomplish different tasks and perform better socially, academically and physically.

AT devices are usually created by biomedical engineers with functionality as the primary object for their clients. However, most of these devices lack essential things to help users psychologically and monetarily. Moreover, in this age, designers are not merely looking for useful objects, but for something that attracts their attention and that of the people around them.

People with disabilities face significant challenges that can impact their lives. Being accepted is one of the principal concerns for the users, and the implementation of Industrial Design in the development of these AT devices has been mind-changing in the people using them. AT devices have been evolving and becoming more aesthetically attractive, ergonomic, easy to use and more importantly, they are becoming devices that create self-esteem in the users. Transforming that “Thing” that can be seen as a fearful object for others into art without compromising function, form and aesthetics

Most devices found in the market can be amazing, but all of them have one thing in common: they are expensive. The biggest market for all these devices is in third-world countries, but potential users are not able to afford these kinds of devices. Design and new ways of production and materials are helping to create products that are accessible and functional for everyone.

As Donald Norman said in his book The Design of Everyday Things, “Design must be thought of as a total experience.” (Norman, 2011) This paper presents problems in the biomedical engineering process and calls for the creation of AT devices that implement Industrial Design in their process that will lead to successful and affordable devices within everyone’s reach.

(Schools, 2017) (Education, 2018) (Whitcliff, 2015)

If some steps from the Industrial Design process are implemented in the development of AT devices, future objects for people with disability could be affordable and aesthetically attractive, easy to use, ergonomic and creating emotional satisfaction for the users.

2. Methodology

For this paper qualitative research is used that aims to understand the principles of AT development and human behaviors with the interaction of these devices. The biomedical engineering process was used to create AT devices and the Design process from the INTI was used to compare them with different objects. Both processes were tested with one product design device and with an AT device created by biomedical engineers, to have a better understanding and approach to dealing with the strengths and weaknesses of each, which leads to a better process for the further development of these devices.

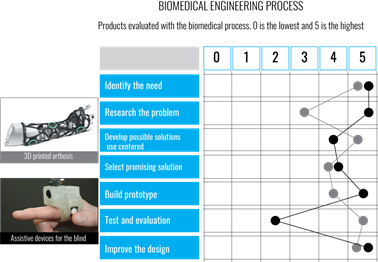

2.1. Analysis of Biomedical Process

When developing a product, biomedical engineers consider several steps to create functional objects. Most of the time the aesthetics of the product is not the primary concern for them. They must deal with different electronic and security problems to improve the interaction with the user. The primary biomedical process was evaluated by picking different products and evaluating specific points showing the weak and strong points in the process.

Black Points and Lines: Color black represents the AT device used to test the Biomedical Engineering process

Grey Points and Lines: Color grey represents the ID device used to test the Biomedical Engineering process

Figure 1: Biomedical Engineering Process to create AT devices

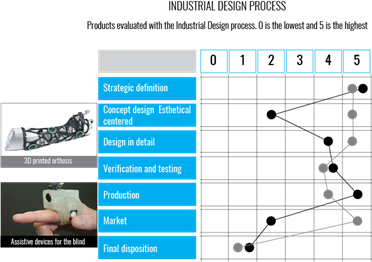

2.2. Industrial Design Process

Taking as a reference the design process (phases for product development) of INTI, the methodology was evaluated in the market, and different weak and strong points were identified.

The Industrial Design process considers important elements to create products. When designing for disabilities, designers don’t just consider aesthetics, but the human factors receive greater emphasis including ergonomics and usability, before the product can be configured in an attractive way.

Black Points and Lines: Color black represents the AT device used to test the Biomedical Engineering process

Grey Points and Lines: Color grey represents the ID device used to test the Biomedical Engineering process

Figure 2: Industrial Design Process

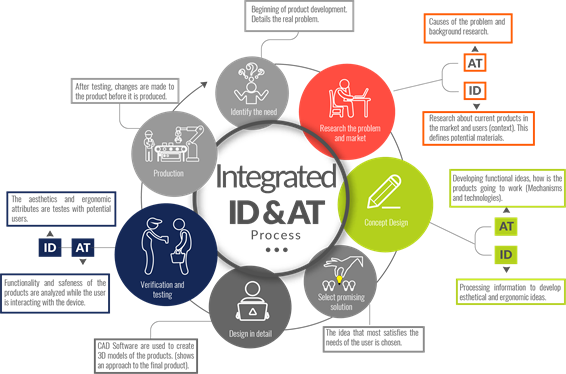

After evaluating both processes the similar elements of both were taken, combining each of them with their process contribution. These contributions benefit the process by having different research backgrounds and interacting with patients and doctors to identify every possible need.

A different approach to concept design was taken including product verification and testing of both processes, considering more elements at the time of making the concept designs and testing the prototypes with the users.

3. Results

Combined Process for Successful AT Development

It was concluded that the best way to create assistive technology devices is to include different parts of the design process. Industrial Design has strength when developing products—the emotional and human factors—and the aesthetical configuration of the product depends on the interaction and research made by Industrial Designers.

The Innovation brought by Designers also helps companies gain a place in the market. The contribution of different tools and points of view to create valuable products works as a strategy for companies in development

Figure 3: Integrated Industrial Design Process and AT Process (Used in Biomedical Engineering)

1. Identify the need: Before any further research patients and doctors’ points of view are heard about the main problem to give a direction to the research.

2. Research the problem and market: After getting the feedback from doctors and patients both AT and ID start their research. AT is in charge of finding the different causes of the problem and future development of the disability. ID finds different solutions already in the market, and defines possible users, materials, configurations.

3. Concept Design: ID considers Human factors, usability, ergonomics and aesthetics when creating concepts. AT focuses more in the functionality and usability of the device.

4. Select promising solution: The concept that is closest to assisting the patient with all or most of the problems is chosen.

5. Design in detail: CAD models are made to have a better approach to the look and functionality of the concept chosen.

6. Verification and testing: Using potential users (Patients and Doctors) the prototype is tested. ID evaluates the human factors, usability, ergonomics and esthetical components of the device while AT evaluates the functional and safety components. All error is detected and fixed before producing the device. (Repeat this step as much as needed.)

7. Production: The first production of the device is small. In this way problems in the device or the manufacturing process are detected before making a large production

4. Discussion

Industrial Design helps a company to be competitive in their market niche. As part of the process of development, they must learn to empathize with the audience for whom they are designing. By using the design thinking process, where the user frequently engages for feedback throughout the design process, industrial designers play an important role in making sure that product launch is successful. (Arts, 2017)

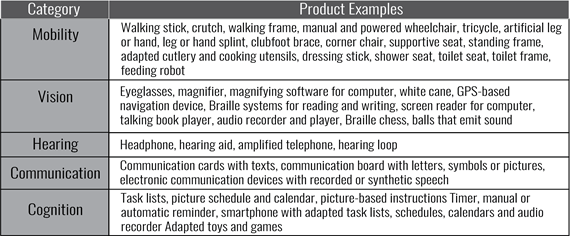

There are various definitions of AT: The International Classification of Functioning, Disability, and Health (ICF) defines assistive products and technology as any product, instrument, equipment or technology adapted or specially designed for improving the functioning of a person with a disability. The International Organization for Standardization (ISO) defines assistive products more broadly as any product, especially produced or generally available, that is used by or for persons with disability: for participation; to protect, support, train, measure or substitute for body functions/structures and activities; or to prevent impairments, activity limitations or participation restrictions. (Unicef, 2015)

For most people technology makes things more comfortable, but for people with disabilities, technology makes things possible. Industrial Design, as a part of the product process, makes objects functional and esthetically attractive against the competition in the market. Awareness of the value of good design is at an all-time high. Good design is recognized as a significant differentiator in ensuring product success in a crowded global market. Evidence abounds that more people in business or society understand that. (Joyce Thomas, 2006)

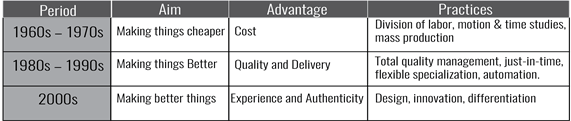

Figure 4, from the European Commission Directorate’s 2012 General Regional Policy Report, illustrates that innovation is a crucial determinant of competitive advantage. Historically, the competition involved making things cheaper, faster, and better, but in today’s markets, “Making better things” means authentically addressing the user’s experience through design, innovation, and differentiation. (Arts, 2017)

Figure 4: Seeking Competitive Advantage

Assistive Technology plays an essential role for the person that uses it, not just for the functional benefits that it gives them, but also the impact it has on intangibles such as self-image, self-esteem, and the sense of self-worth. Industrial Design in the development of these devices helps to create valuable and attractive objects which are then perceived by people to only “work better.”

(Tellez, 2014)

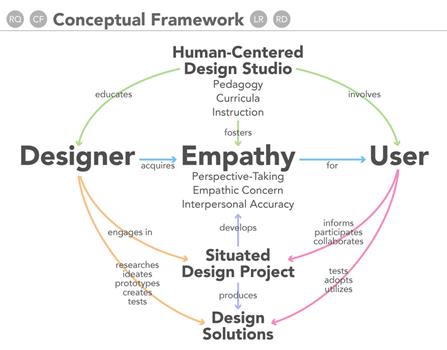

The Interaction Design Foundation states that empathy is crucial to a human-centered design process such as Design Thinking, and empathy helps design thinkers to set aside his or her own assumptions about the world in order to gain insight into the users as well as their own needs. (Dam & Siang, 2018)

In the whole process of AT development, feedback from the doctors and patients are important. As designers, understanding the user and his or her feelings helps to direct the design based on needs, desires and preferences of the user.

Objects for people with disabilities have two kinds of interactions, the Direct and the Indirect, where Direct is the first contact with the user while the Indirect is what other people see. Most assistive devices can be expensive and sometimes unaffordable for people; however, the National Endowment for the Arts has shown that implementation of Industrial Design by companies lowers costs through improved manufacturing and reduction of product-to-market time. (Arts, 2017).

Examples of Assistive Technology Devices.

Figure 5: Examples of AT

As more as devices come to market, competition for market share drives innovation in one or more of the areas of product, process, or in their manufacturing operations.

A wide variety of devices launched to the market allow companies to have more innovative options either in the product, process or their manufacturing operations. Kaan Turnali notes the importance of Industrial Design in his book How Design Thinking Can Help Your Business: “It can be as effective in technology or education as it may be in services or manufacturing. It could result in new products and services for customers or improved processes and productivity gains for internal operations. If applied with equal fervor, it can even transform HR, finance, marketing, or operations teams—turning them into lean and agile profit centers. (Turnali, 2015)

Successful Assistive Technology Designs

(Innovations, 2018) (Ramey, 2014)

Industrial Designers are educated to apply sensory perception and different theories of human factors in their designs when it is suitable, allowing for the creation of safe and efficient products. In the article “Addressing Human Factors and Ergonomics in Design Process, Product Life Cycle and Innovation: Trends in Consumer Product Design” it states that ergonomics and Industrial Design have an anthropocentric focus, and that the critical point for a successful process integrating Industrial Design is how designers understand human beings and their role in the development process. (García, Lange, Puentes, & Ruiz, 2011)

Finally, Industrial Designers possess a comprehensive set of skills, such as business modeling, research, observation, manufacturing, human factors, ergonomics, marketing, and design principles, and these skills make them an essential component for product development and business success.

5. Conclusion

Companies that have incorporated Industrial Design into their AT products will find that it leads to innovations in materials and process that benefit the user. Industrial Design improves goods and services and lowers the cost of products and manufacturing, making AT devices more affordable for more people.

Industrial Design is gaining greater acceptance into the industry of product development and services. The design process combined with other disciplines creates a powerful convergence to create and execute solutions for problems of functionality, physical ergonomics, human factors, form, usability, marketing, sales, etc.

Industrial Design considers human factors, ergonomics, usability and aesthetics which leads to the creation of better products (AT Devices) with less flaws.

Good Design allows for the exploration of new manufacturing processes and product improvements, and for being more competitive in a global market, taking into consideration price, features, quality and product innovation.

Acknowledgment

I want to thank Eric S. Rainbolt for his assistance in editing this paper.

References

[1] Arts, N. E. (2017). Industrial Design A Competitive Edge for U.S. Manufacturing Success in the Global Economy. Washington, DC.

[2] Dam, R., & Siang, T. (2018). Design Thinking: Getting Started with Empathy. Retrieved from The Interaction Design Foundation: https://www.interaction-design.org/literature/article/design-thinking-getting-started-with-empathy

[3] Education, S. U. (2018). Vantage. Retrieved from Assistive Technology Devices, Software, and Apps: http://soe.syr.edu/centers_institutes/institute_communication_inclusion/what_is_supported_typing/Devices.aspx

[4] García, G., Lange, K., Puentes, D., & Ruiz, M. (2011). Addressing human factors and ergonomics in design process, product life cycle and innovation: Trends in consumer product design. pp. 1,2.

[5] Innovations, A. (2018). Assisitive Innovations. Retrieved from iEAT Feeding Robot: https://www.assistive-innovations.com/en/contact/45-general/209-contact

[6] Joyce Thomas, D. M. (2006). People with Disabilities Designing for the Mainstream User: Empathic Design Research.

[7] Norman, D. A. (2011). The Design of Everyday Things. Tantor Audio.

[8] Pullin, G. (2010). Design Meets Disability.

[9] Ramey, K. (2014). Use

of technology. Retrieved from USE OF TECHNOLOGY TO CHANGE EDUCATION FOR

STUDENTS WITH DISABILITIES:

https://www.useoftechnology.com/students-disabilities/

[10] Robitaille, S. (2010). The Illustrated Guide to Assistive Technology and Devices. New York: Demos Medical Publishing, LLC.

[11] Schools, C. P. (2017, October 05). Student with bilateral splints for stylus to access an IPAD. Assistive Technology CPS. Chicago.

[12] Tellez, A. (2014, December ). Empathy Promotion in Industrial Design Education. Raleigh, North Carolina .

[13] Turnali, K. (2015). World Economic Forum. Retrieved from How can design thinking help your business?: https://www.weforum.org/agenda/2015/05/how-can-design-thinking-help-your-business/

[14] Unicef. (2015). Assistive Technology for Children with Disabilities: Creating Opportunities for Education, Inclusion and Participation.

[15] Virgile, C. B. (2008). Assistive Technology: A Tool for Enhancing Classroom Instruction for Students with Learning Disabilities.

[16] Watanabe, T. (2014). Industrial Designers as a Driver of Technology Innovation: Evidence from a Japanese electronics industry. Tokio.

[17] Whitcliff, J. (2015). Hearing Aid Buyer Today. Retrieved from Facts About The Cost Of Hearing Aids: http://hearingaidbuyertoday.com/facts-cost-hearing-aids/

[18] World Health Organization. (2018). Retrieved from http://www.who.int/disabilities/en/